UGR<19 Prism Optics

Product Details:

- Material Options: PMMA for best optical performance, PC for impact resistance, and PS for cost-effective solutions.

- Thickness Range: Standard 1.2–3 mm; custom options available in 4 mm and 5 mm.

- Sheet Sizes: Standard 1220 × 2440 mm, with a maximum size of up to 1250 × 3050 mm.

- Glare Control: UGR <19 rating.

- Fire Safety: Certified to UL 94 (HB, V2, V0) and TP(a) rating.

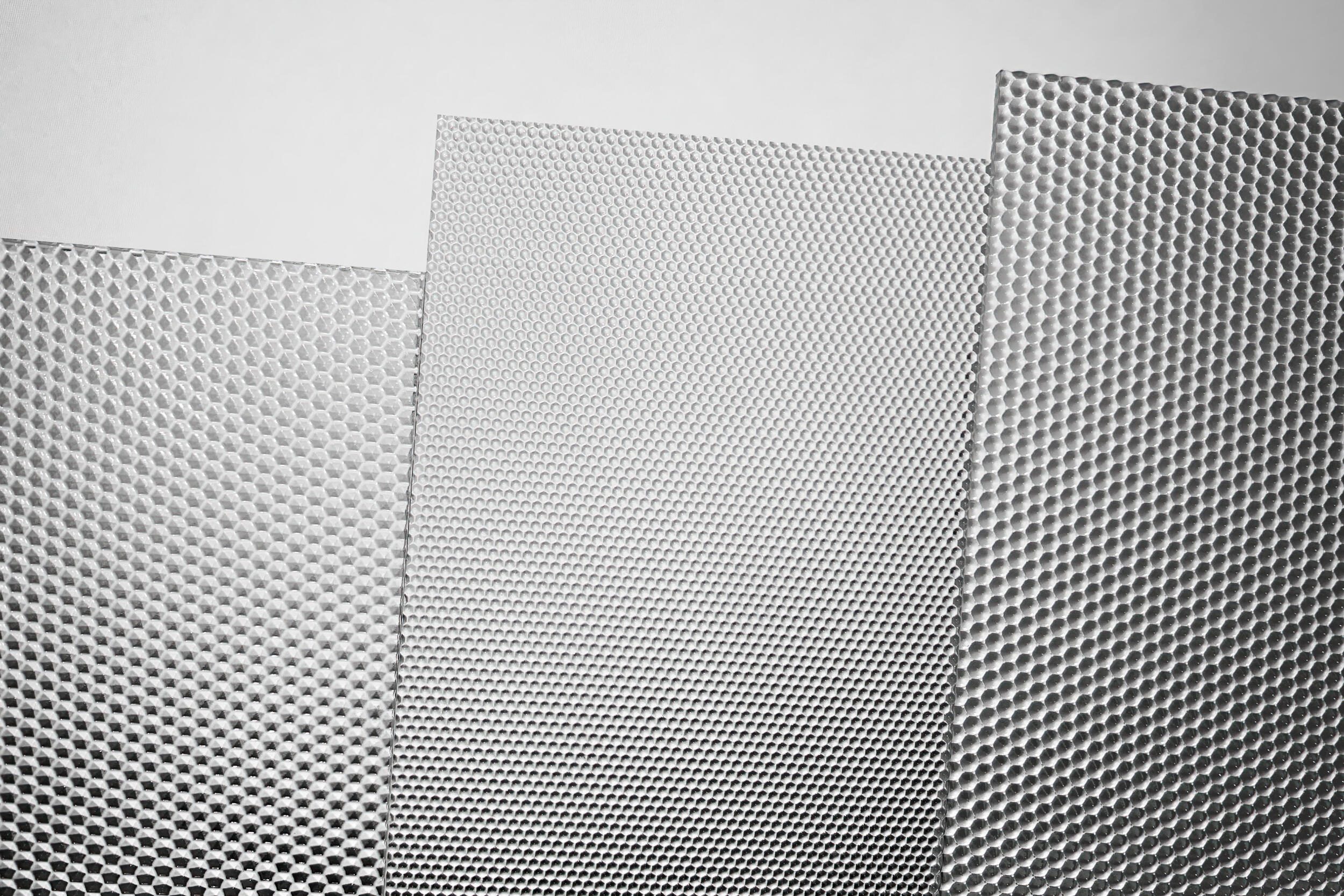

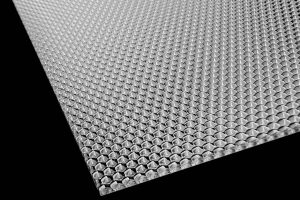

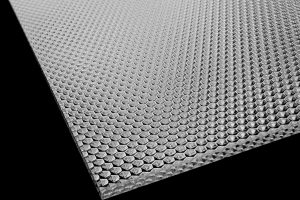

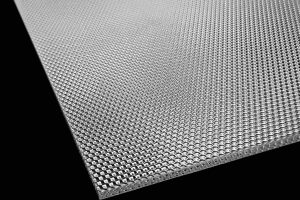

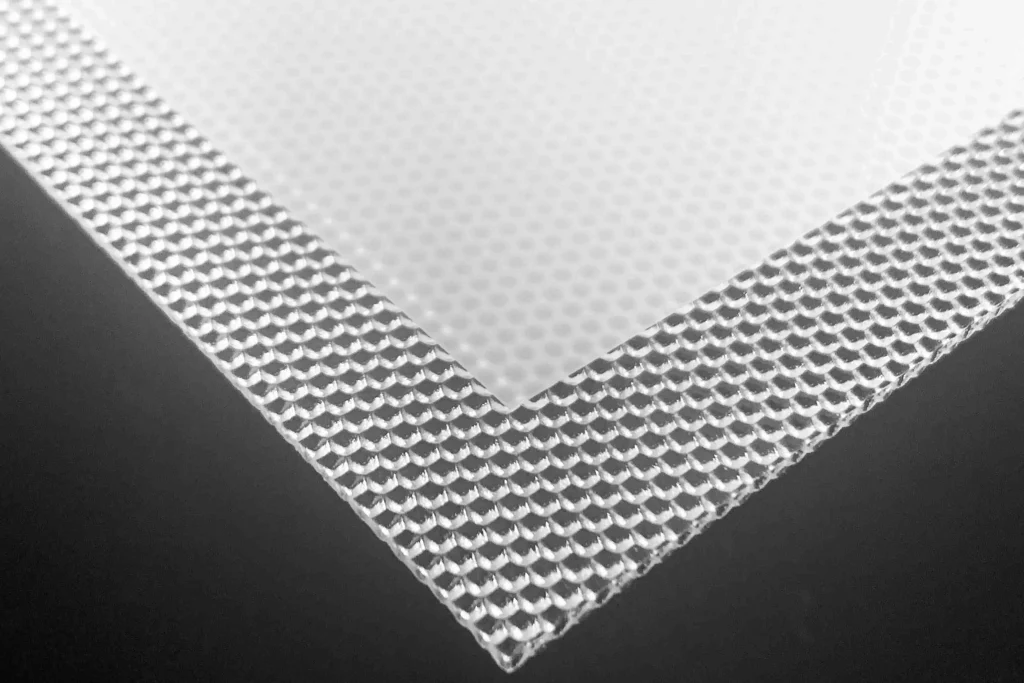

- Prism Designs: Convex and concave hexagon.

Description

Lighting should feel natural and comfortable. Our microprismatic lenses are designed to reduce glare and create a pleasant visual environment, meeting European office lighting standards (EN 12464-1) with a UGR rating below 19. That means clearer focus, less eye strain, and a more productive workspace.

Trusted by leading LED lighting brands, these prismatic sheets are widely used in offices, schools, and commercial spaces where balanced, high-quality light is essential. The precise microprism structure spreads light evenly, eliminating hotspots and delivering consistent brightness across the entire luminaire.

For projects requiring extra safety and durability, we offer TP(a) and V0 fire-rated polystyrene and polycarbonate diffusers with UV stability. This unique material resists yellowing and degradation, ensuring long-term optical performance even in demanding environments.

Different prism patterns are available, each optimized to control light refraction and maximize efficiency, giving designers and engineers flexibility to create the right atmosphere for any application.

The table below provides a detailed technical comparison of UGR<19 microprismatics.

| Series | Product Code | Material | Thickness mmin | LT (%) | Prism | Prism Array | Light Refraction | Thickness in mmin |

|---|---|---|---|---|---|---|---|---|

Honeycomb | Plexi Honeycomb | PMMA | 1.5, 2.0 & 3.0 | 94 | Convex Hexagon |  |  | 0.059, 0.078 & 0.118 |

| S Honeycomb | PS | 1.2 & 1.5 | 94 | 0.047 & 0.059 | ||||

| S Honeycomb TP(a) | PS TP(a) | 1.2 & 1.5 | 94 | 0.047 & 0.059 | ||||

| Poly Honeycomb | PC | 1.2 & 1.5 | 90 | 0.047 & 0.059 | ||||

| Poly Honeycomb V0 | PC V0 | 1.2 & 1.5 | 90 | 0.047 & 0.059 | ||||

Hexagon | Plexi Hexagon | PMMA | 1.5 & 2.0 | 94 | Concave Hexagon |  |  | 0.059 & 0.078 |

| Poly Hexagon | PC | 1.2 & 1.5 | 90 | 0.047 & 0.059 | ||||

| S Hexagon | PS | 1.2 & 1.5 | 94 | 0.047 & 0.059 | ||||

| S Hexagon TP(a) | PS TP(a) | 1.2 & 1.5 | 94 | 0.047 & 0.059 | ||||

Mikroprismen | Plexi Mikroprismen | PMMA | 1.5 | 94 | Convex Micro Hexagon |  |  | 0.059 |

MiniHexa | Plexi MiniHexa | PMMA | 1.5 | 94 | Concave Micro Hexagon |  |  | 0.059 |

| Poly MiniHexa | PC | 1.2 | 90 | 0.047 |

Explore each microprismatic type on its own dedicated product page.

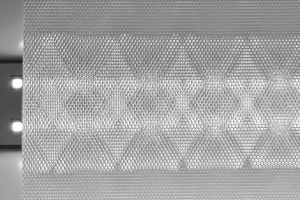

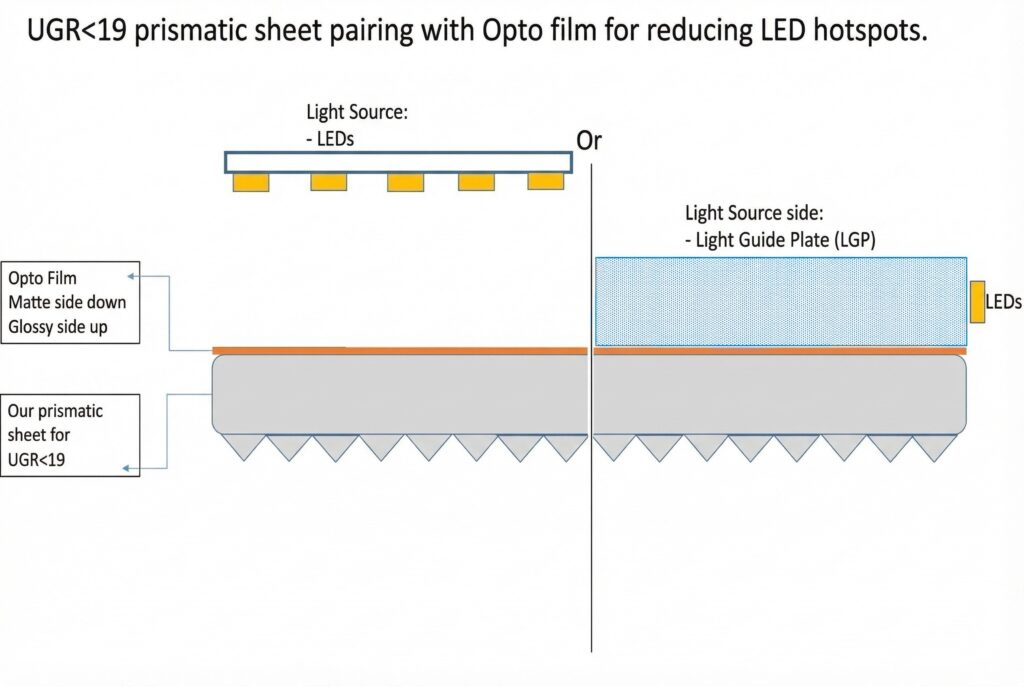

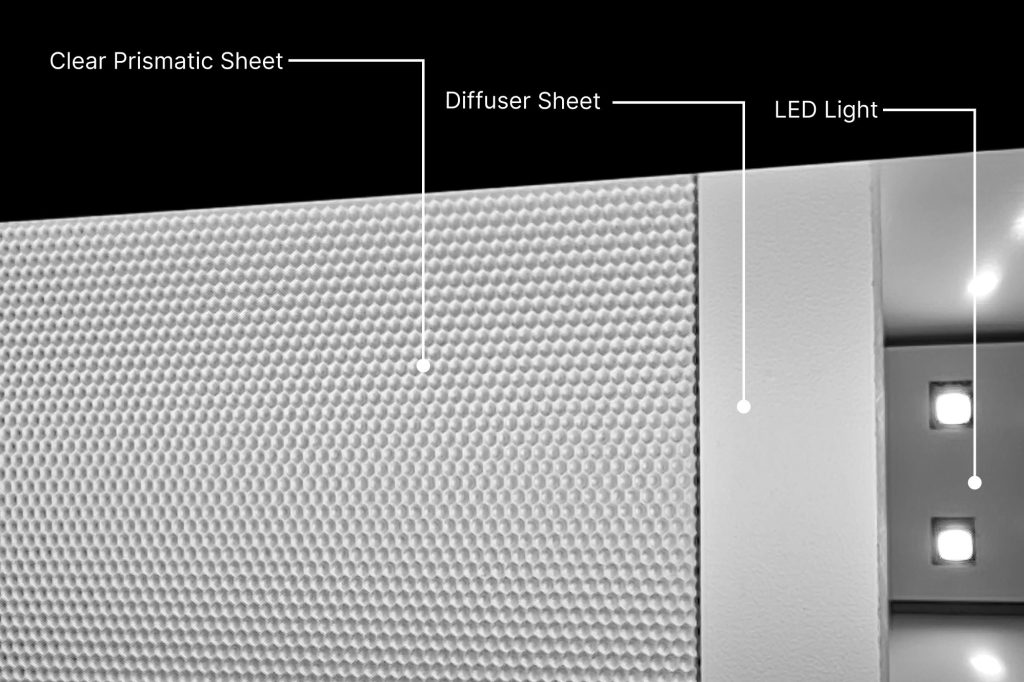

Microprismatic Sheet + Diffuser Film = The UGR<19 Solution

Combining clear microprismatic sheets with diffuser films or sheets is a common practice to achieve a soft, opal-like glow while reducing the UGR value for comfortable, low-glare illumination.

The Microprismatic Sheet (Structure): Uses thousands of tiny prisms to de-glare the light, redirecting it downwards (usually within a 65° cutoff angle) to prevent light from shining directly into the eyes.

The Diffuser Film/Sheet (Uniformity): Sits behind or on top of the prisms to hide LED “hotspots” and soften the light, ensuring the output is smooth without losing the glare-control properties of the prisms.

We recommend pairing the microprismatic sheet with a diffuser film:

- Opto90 PET225 or

- Opto80 PC200

For more robust or demanding applications we recommend the following translucent diffuser sheets in 1.2 or 1.5mm thickness:

Poly80

Plexi90 Silk or Frost,

S92 or