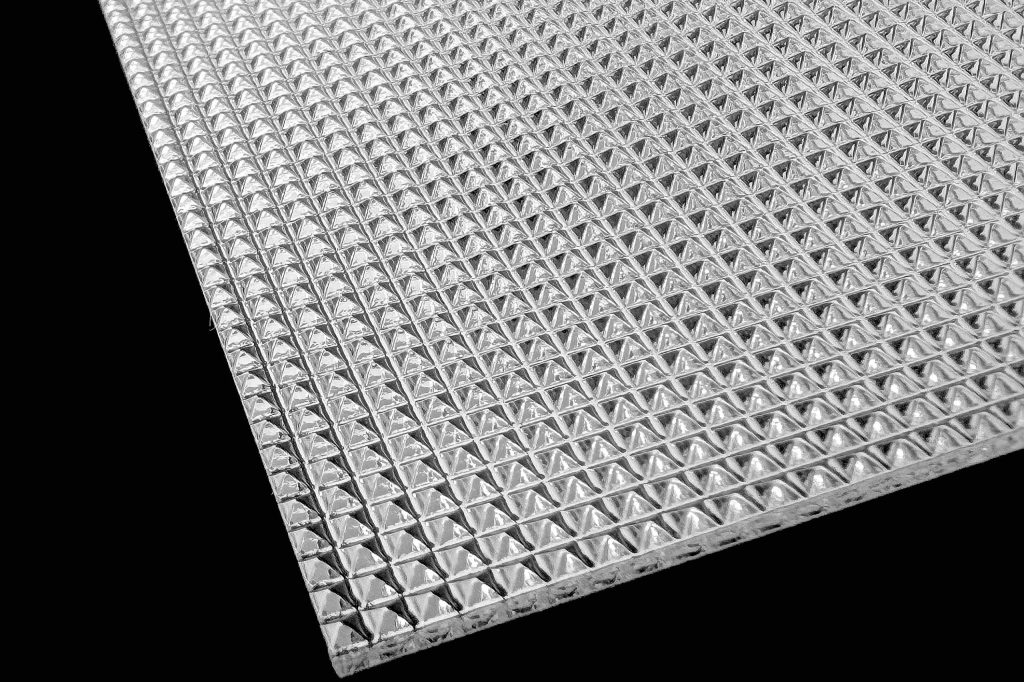

Pyramid

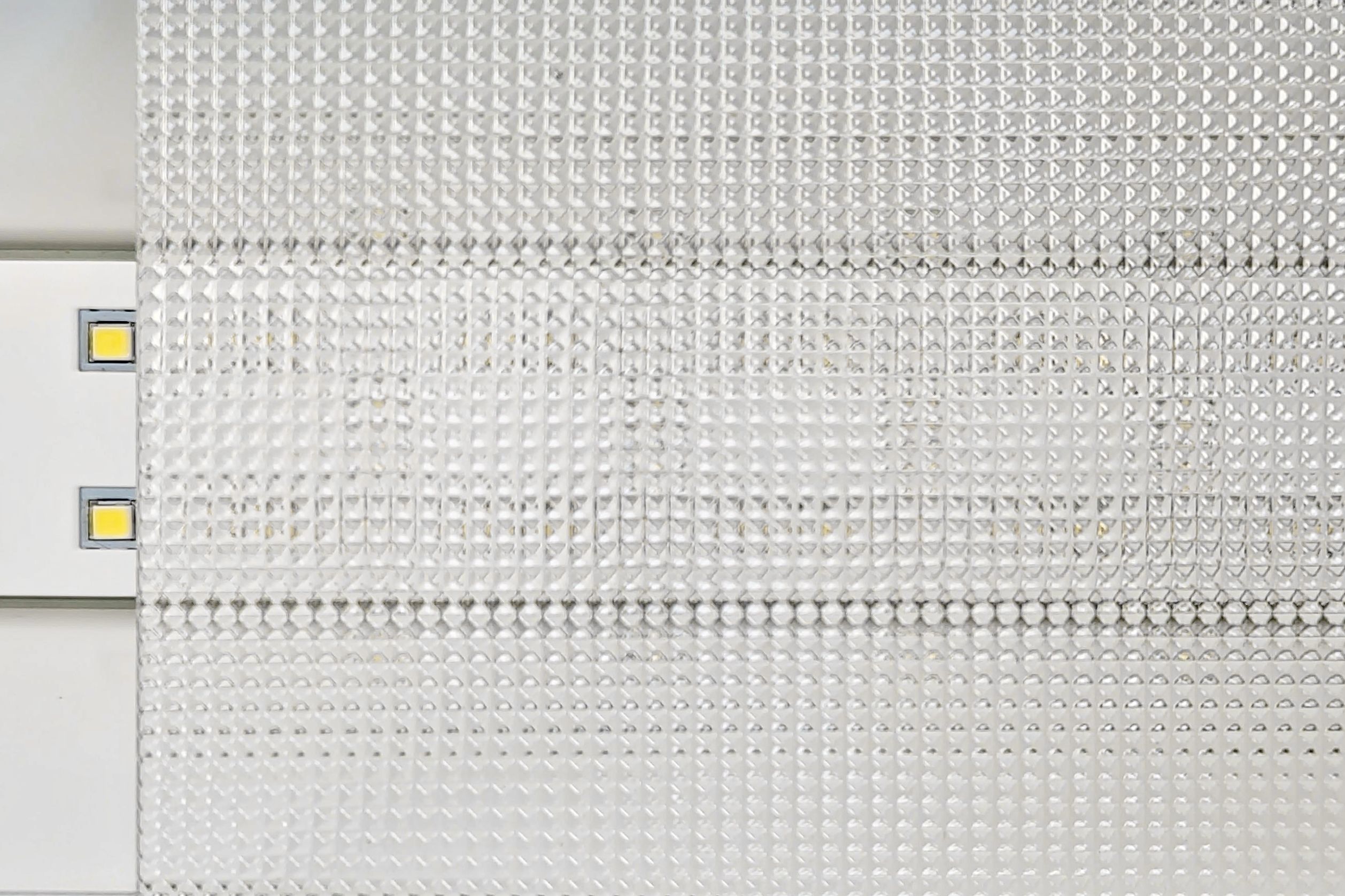

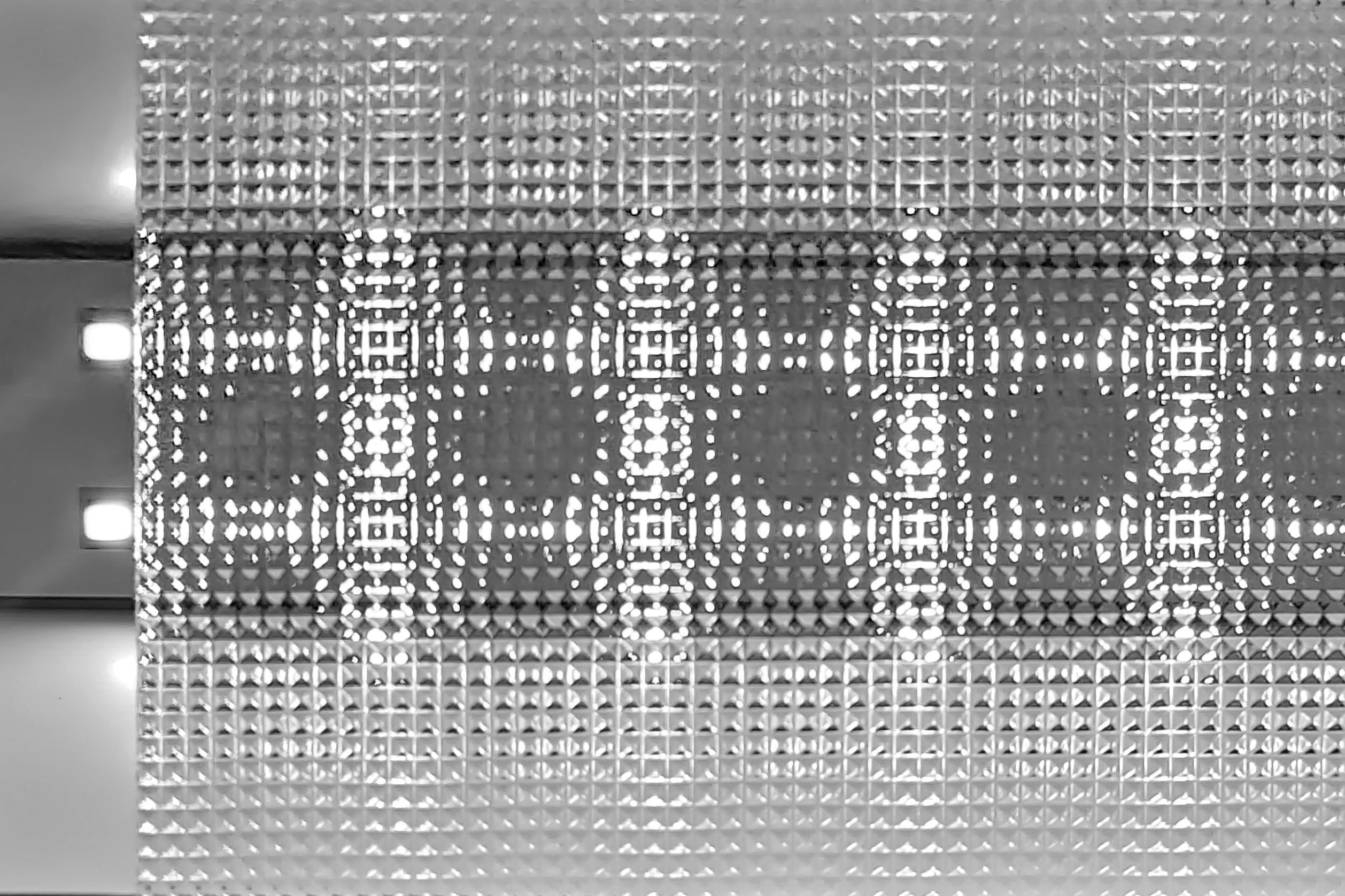

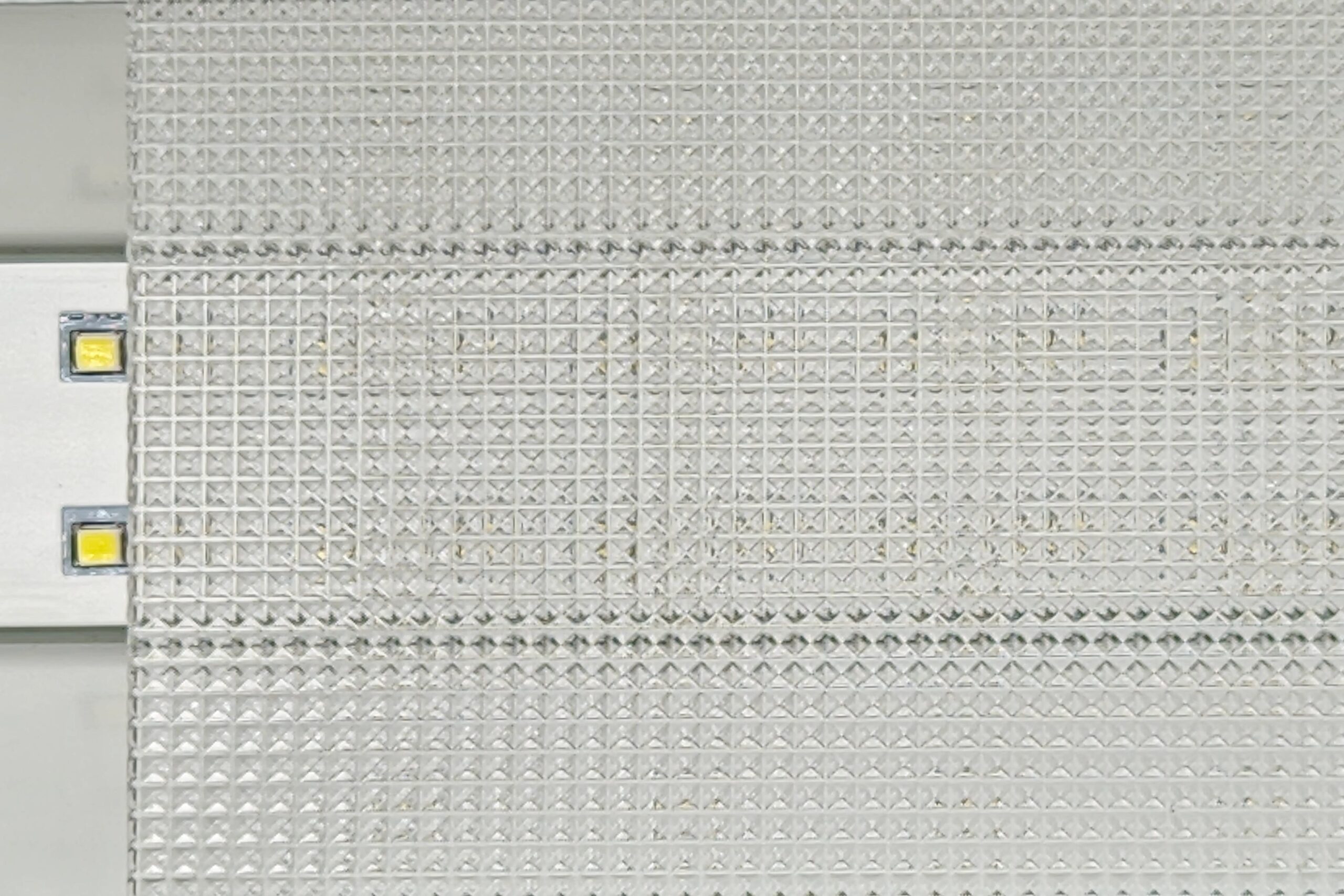

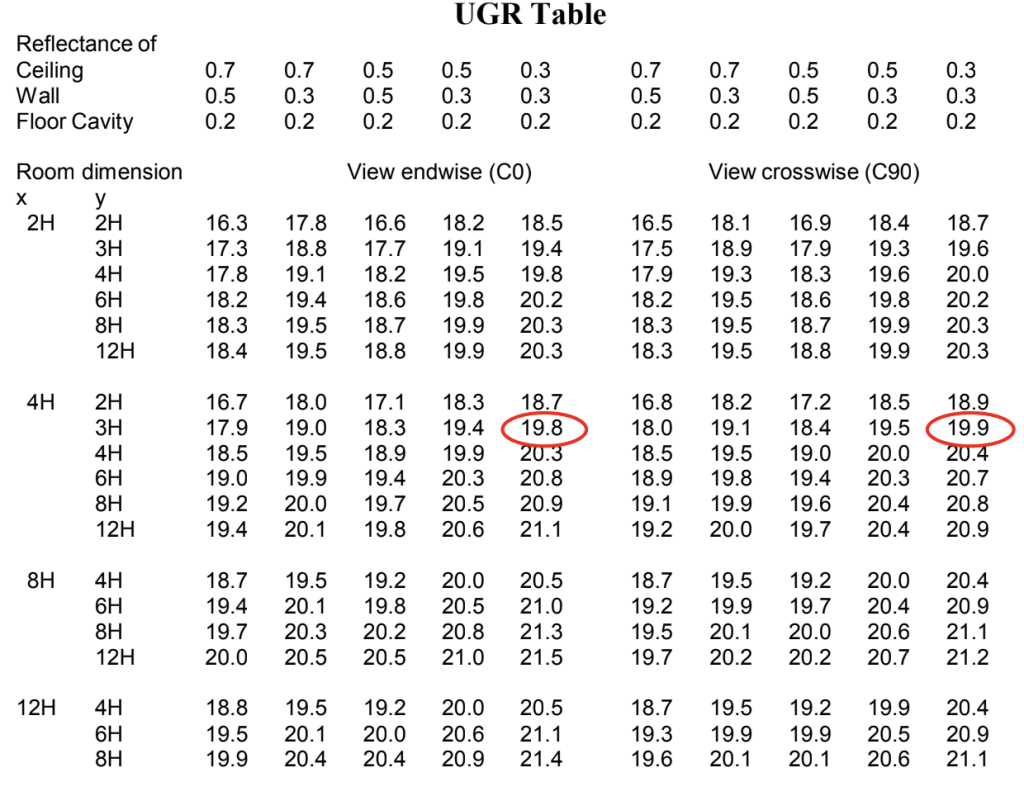

The Pyramid Prismatics series uses multi-faceted pyramidal geometry to provide controlled light distribution, glare reduction for UGR<19, and enhanced visual comfort. Symmetrical prism faces and controlled facet angles balance luminous efficiency with effective high-angle luminance control, making it suitable for a wide range of architectural applications.

- Balanced Efficiency & Comfort: Optimized for architectural environments.

- Multi-directional Glare Control: Symmetrical facets redirect light across horizontal and vertical planes.

- High-Angle Cutoff: Reduces high-angle luminance for improved comfort.

- Uniform Luminance: Better uniformity than single-axis prism structures.

- Efficient Beam Shaping: Controlled light distribution without significant loss.

Certifications

Products Comparison

| Product Code | Material | Thickness mmin | Light Transmission | Fire Rating | Key Features | Thickness Range in mmin |

|---|---|---|---|---|---|---|

| Plexi Pyramid | Acrylic (PMMA) | 1.8 | 94% | UL94 HB | UGR<19, UV-stable | |

| S Pyramid | Polystyrene (PS) | 1.5 | 94% | UL94 V2/V0 | UGR<19, Lightweight, cost-effective | 0.059 |

| Plexi Pyramid 2 | Acrylic (PMMA) | 2 | 94% | UL94 V0 | Bigger pyramid pattern | 0.078 |

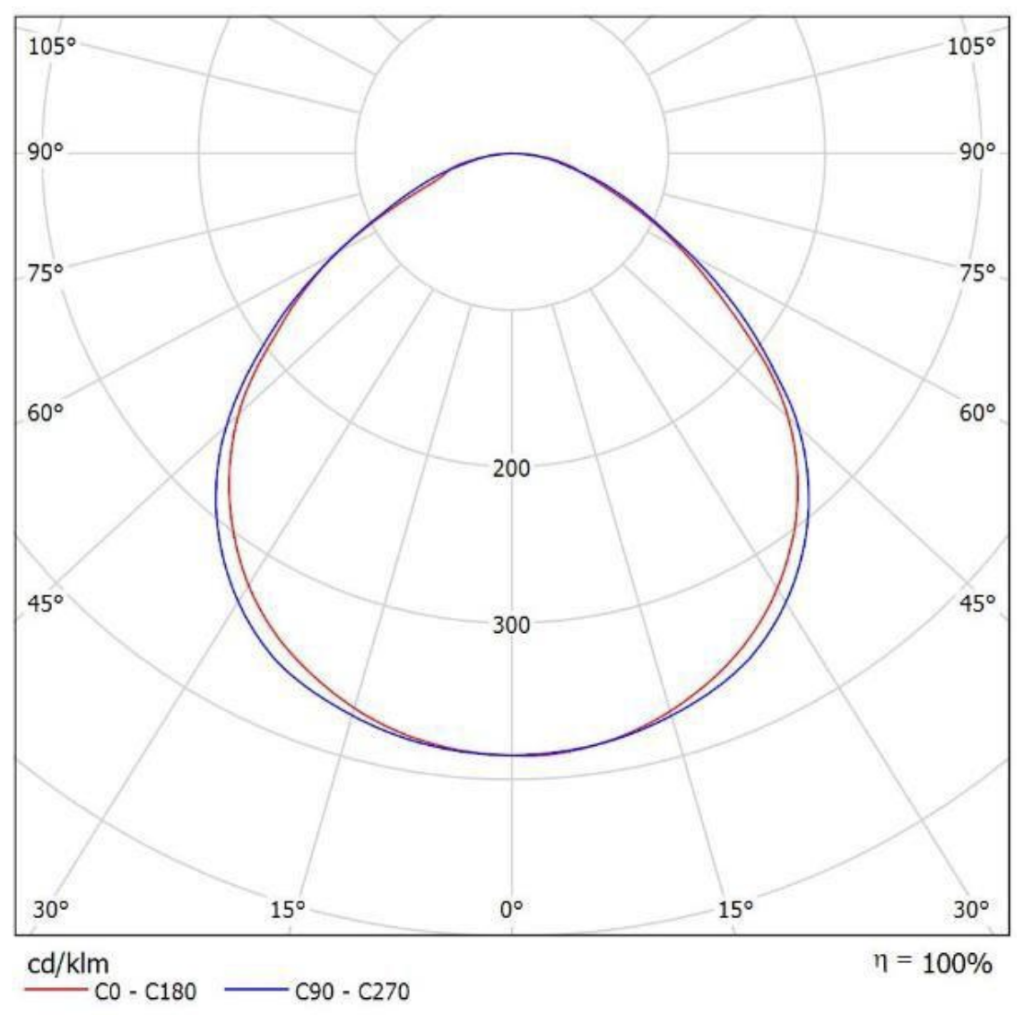

Photometric Data

Optical Performance & Refraction

Applications

More Information

Applications

- Workplaces requiring screen-based task lighting (computer work, design studios)

- Office lighting (open-plan offices, meeting rooms)

- Schools and universities (classrooms, libraries, study halls)

- Healthcare facilities (hospitals, clinics, laboratories)

- Public buildings (airports, museums, government offices)

- Commercial lighting (retail stores, shopping malls)

- Architectural lighting (modern interior designs, co-working spaces)

- High-end residential (kitchens, study rooms, home offices)

Available Widths and Lengths

The standard sheet width is 1220 mm. For special projects, the extrusion width can be adjusted up to a maximum of 1250 mm upon request.

Our standard lengths are 1220 mm, 1830 mm, 2440 mm, and 3050 mm. Custom lengths can also be produced upon request to suit your specific needs.

Custom Cutting, Machining & Fabrication

We provide complete processing services to deliver prismatic sheets in the exact size and finish you need, from simple cuts to precision machining.

Available options include:

- Milling to create steps, grooves, or custom profiles

- CNC machining for precise shapes and patterns

- Laser cutting for smooth edges and complex geometries (up to 1300×1300mm)

- Saw cutting for standard sizing and trimming.

- Bonding and assembly of multiple sheet layers

- Edge finishing with chamfers, bevels, and rounded edges

Saw cutting capability: Up to 3050mm long and >30mm wide.

Tolerances:

L:±1mm

W:+0.6 / -0mm (Unilateral Plus) or +0 / -0.6mm (unilateral minus)

Materials: Comparison of PMMA, PC, and PS

Use this comparison table to quickly understand the differences and find the best option for your lighting project.

| Property / Feature | PMMA (Acrylic) | PC (Polycarbonate) | PS (Polystyrene) |

|---|---|---|---|

| Light Transmission | Very high | High | High |

| Impact Resistance | Low – brittle, can crack under stress | Very high – shatter-resistant | Low – brittle |

| Heat Resistance (Continuous Use) | 80–90°C | 120°C | 70°C |

| Maximum Short-Term Heat | ~100°C | ~135°C | ~80°C |

| UV Resistance / Weathering | Good (can yellow over long-term) | Moderate UV stability (However we add UV stabilizer) | Fair (Prone to yellowing)However we add UV stabilizer. |

| Flammability / Safety | Moderate (UL94 HB) | Better (UL94 V-2/V-0 with additives) | Moderate (UL94 HB) |

| Chemical Resistance | Good (resistant to mild acids/alkalis) | Excellent – resists most chemicals | Poor – sensitive to solvents |

| Weight / Density | 1.18 g/cm³ | 1.2 g/cm³ | 1.05 g/cm³ |

| Processing / Fabrication | Thermoforming, laser cutting, CNC. | Good for thermoforming, no laser cutting, CNC. | CNC. |

| Cost | Medium | High | Low |

| Durability / Lifespan | Moderate – good indoor use | Very high – suitable for harsh/industrial environments | Fair – medium-term indoor use |

| Common Applications | Office LED panels | Industrial/warehouse lighting, outdoor luminaires, impact-prone areas | Cost sensitive projects |

Product Tolerances

The three materials (PMMA, PC and PS) have similar tolerances.

| Property | Value |

| Thickness | ±3% |

| Mother board Length / Width | ±3.0 mm |

| Cut-to-Size Length / Width | ±0.3 mm |

| Light Transmittance & Haze | ±2% |

Note: PMMA has the highest thermal expansion coefficient among diffuser materials. This means it can expand in hot conditions and contract in cold conditions. Use our Thermal Expansion Calculator to predict the final dimensions before installation.

Packing

At Hexatron Technologies, we take great care in packing our diffuser sheets to ensure they reach our customers in perfect condition.

1. Standard Sheet Packing

- Mother Sheets: Large sheets (up to standard extrusion sizes) are stacked on pallets or crates.

- Final Cut / Cut-to-Size Sheets: Smaller sheets are carefully wrapped and separated with protective films or kraft paper, then bundled to avoid bending or warping.

2. Protection Methods

- Surface Protection Film: All diffuser sheets are supplied with a removable protective film to prevent scratches and contamination.

- Edge Guards / Corner Protectors: To prevent chipping or denting during handling and shipping.

3. Palletization & Securing

- Sheets are stacked on pallets or crates with interleaving layers and secured with straps or stretch film to prevent movement during transit.

- Maximum stack height is calculated based on sheet thickness and material to avoid warping or deformation. A pallet of 1.5 tons is the maximum weight.

4. Shipping & Handling Recommendations

- Flat Storage: Sheets should be stored flat and supported evenly to maintain flatness.

- Climate Considerations: Avoid prolonged exposure to extreme temperatures or humidity, especially for PMMA, to prevent dimensional changes.

- Handling: Use gloves when removing protective film to prevent fingerprints.