Thin LGP

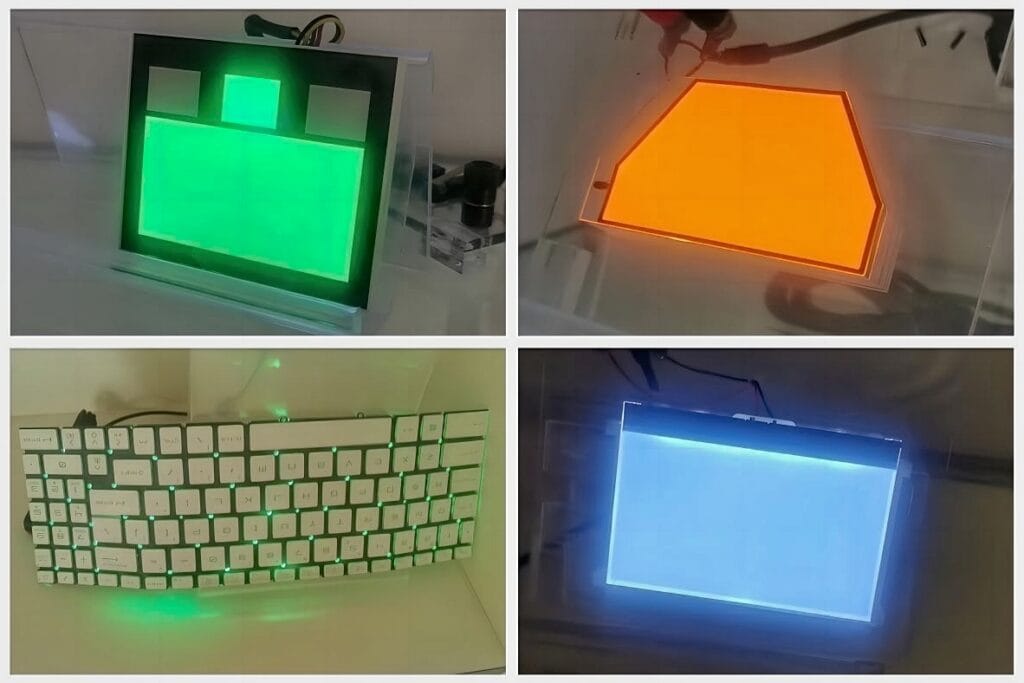

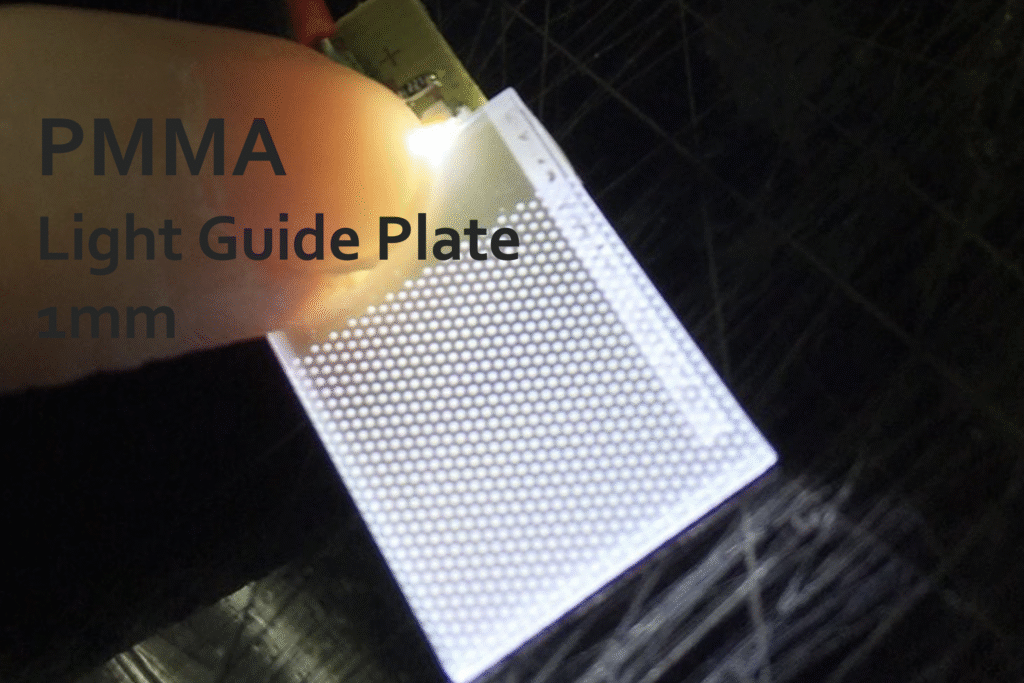

Thin Light Guide Plate (Thin LGP) is an ultra-slim optical solution designed for space-constrained lighting applications requiring uniform illumination and high efficiency in minimal thickness. With a standard thickness of 1 mm, Thin LGPs enable sleek, lightweight, and modern lighting designs without compromising optical performance.

Optimized for backlit displays, signage, and compact LED panels, Thin LGPs deliver even light distribution across the entire surface and can be customized in size and shape to meet specific project requirements.

Certifications

Technical Specifications

| Attribute | Value / Range | |

|---|---|---|

| Material | Optical-grade PMMA or PC | |

| Thickness | <1 mm | |

| Light Input | Edge-lit LED | |

| Surface Treatment | Optimized light extraction pattern | |

| Processing | Precision cutting, custom shaping | |

| Application Type | Ultra-slim lighting systems |

Performance Benefits

Simplified Assembly: System integration reduces design complexity and lead time.

Minimal Thickness, Maximum Impact: Enables ultra-slim lighting designs.

High Optical Efficiency: Efficient light utilization despite reduced thickness.

Clean Visual Appearance: Smooth and even illumination.

Value-Added Services & System Integration

To streamline your LED lighting projects, we offer comprehensive added-value services:

LED & Electrical Integration

- LED module integration

- Connectors and wiring solutions

- Power and control module support

Thermal Management

- Integration of thermal management components

- Optimization for long-term LED reliability

Complementary Optical Components

- Bonded 0.1~0.5 mm diffuser films for visual comfort

- Bonded 0.1~0.2mm reflective films to enhance light efficiency

These services allow customers to receive a ready-to-assemble or semi-assembled optical system, reducing development time and manufacturing complexity.

More Information

Custom Cutting, Machining & Fabrication

Every Light Guide Plate (LGP) is fully customizable to meet your specific design and assembly requirements.

Advanced fabrication technology ensures precision cutting, optical clarity, and consistent quality for all applications.

Capabilities include:

- CNC cutting, milling, and drilling

- Laser engraving for light extraction patterns

- Edge finishing and polishing for high transparency

- Tight-tolerance machining for perfect alignment

Supports both prototype development and mass production with stable, repeatable optical performance.

Typical Tolerances Properties for Optical Grade PMMA

| Property | Typical Value / Tolerance |

| Thickness | ± 0.1 mm (3 to 15mm) |

| Dimensional (length × width) | ± 0.3 mm |

| Material clarity / defects | No inclusions, bubbles, scratches visible; optical grade |

| Uniformity | ≥ 85% uniformity depending on size; for small size often higher |

| Thermal expansion | ~ 7 × 10⁻⁵ / °C |