Laser LGP

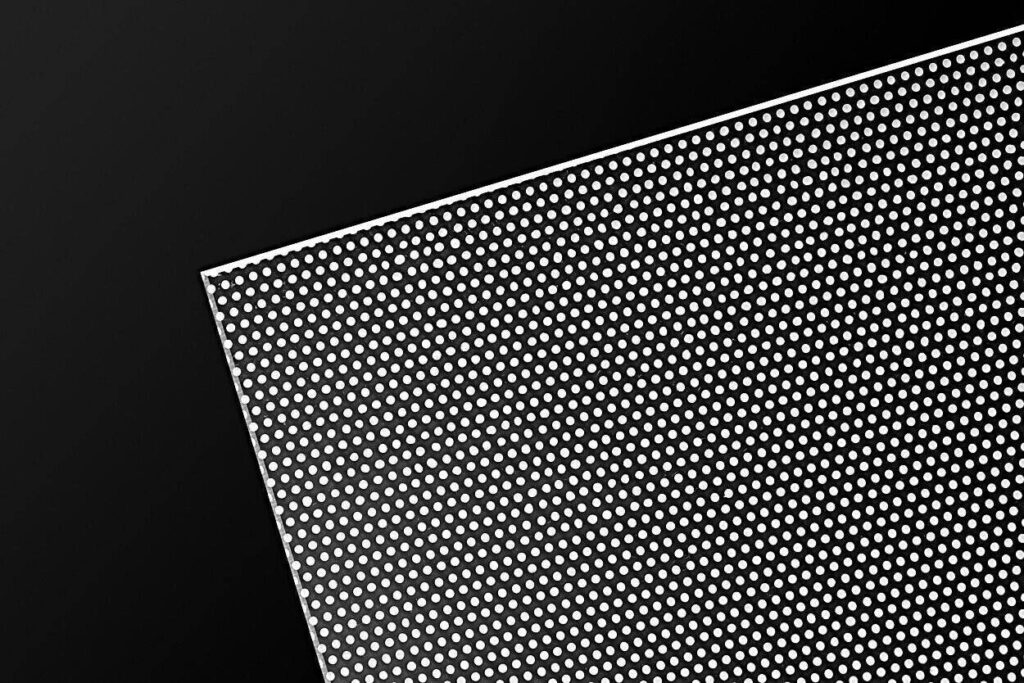

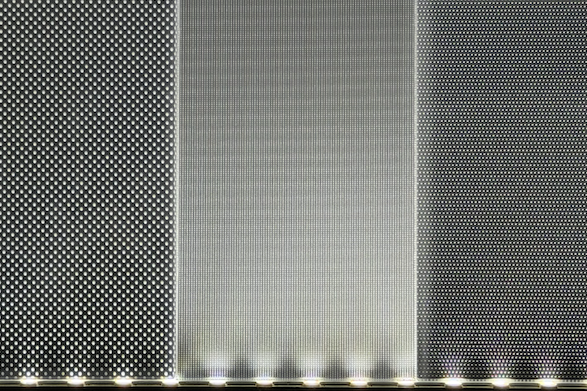

The Laser Light Guide Plate (Laser LGP) is a precision-engineered optical component designed to deliver uniform high-efficiency illumination in LED lighting systems. Using laser-engraved dot patterns, our Laser LGP provides exceptional control of light extraction across the surface, resulting in superior brightness uniformity.

Manufactured from optical-grade PMMA with advanced laser processing technology, the Laser LGP is ideal for applications requiring large-area light distribution, high lumen output, and ultra-thin form factors.

Certifications

Technical Specifications

| Attribute | Value / Range | |

|---|---|---|

| Material | Optical-grade PMMA (acrylic) | |

| Thickness | 2 mm – 15 mm | |

| Maximum Panel Size | Up to 2,000 × 4,000 mm | |

| Surface Treatment | Laser engraved dot pattern | |

| Light Transmission | ≥ 92% (clear PMMA) | |

| Reflection Control | Custom laser dot density design | |

| UV Resistance | UV-stabilized | |

| Operating Temperature | -20°C to +70°C (application dependent) |

LGP Micro-Patterning Technologies

Bespoke Light Guide Plate for every application.

Every LGP is custom-engineered using a proprietary algorithm. By analyzing key variables such as panel dimensions and light-entry points, we optimize the laser dot density for the best uniformity.

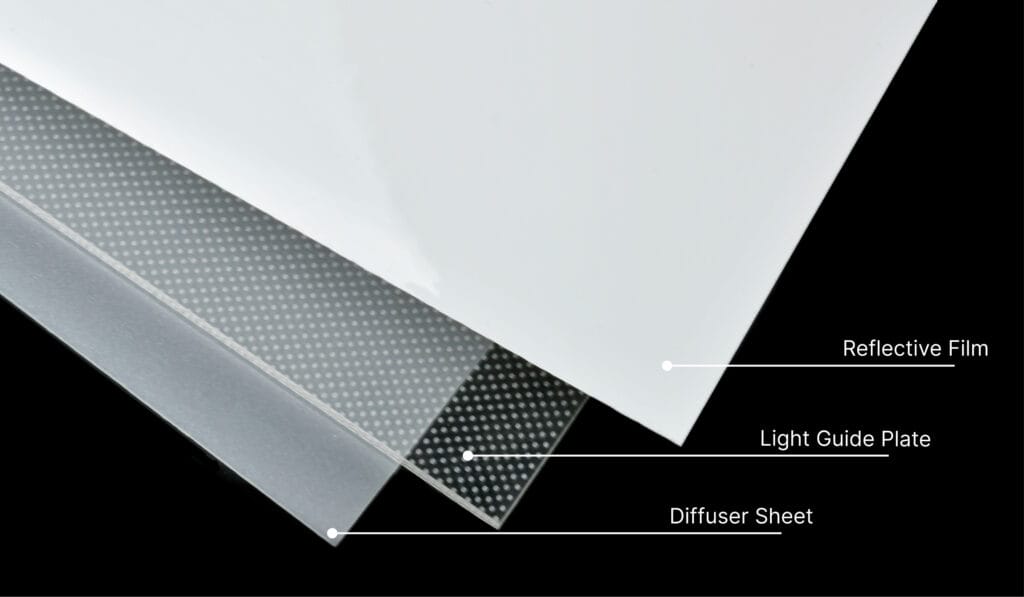

Complement Products

Laser LGPs are typically paired with front diffuser sheets (opal, or UGR<19 optimized).

Back reflective sheets improve output by redirecting backward-emitted light toward the front surface, enhancing overall system efficacy.

We provide a complete “optical bundle” to simplify your supply chain and ensure component compatibility.

More Information

Custom Cutting, Machining & Fabrication

Every Light Guide Plate (LGP) is fully customizable to meet your specific design and assembly requirements.

Advanced fabrication technology ensures precision cutting, optical clarity, and consistent quality for all applications.

Capabilities include:

- CNC cutting, milling, and drilling

- Laser engraving for light extraction patterns

- Edge finishing and polishing for high transparency

- Tight-tolerance machining for perfect alignment

Supports both prototype development and mass production with stable, repeatable optical performance.

Typical Tolerances Properties for Optical Grade PMMA

| Property | Typical Value / Tolerance |

| Thickness | ± 0.1 mm (3 to 15mm) |

| Dimensional (length × width) | ± 0.3 mm |

| Material clarity / defects | No inclusions, bubbles, scratches visible; optical grade |

| Uniformity | ≥ 85% uniformity depending on size; for small size often higher |

| Thermal expansion | ~ 7 × 10⁻⁵ / °C |