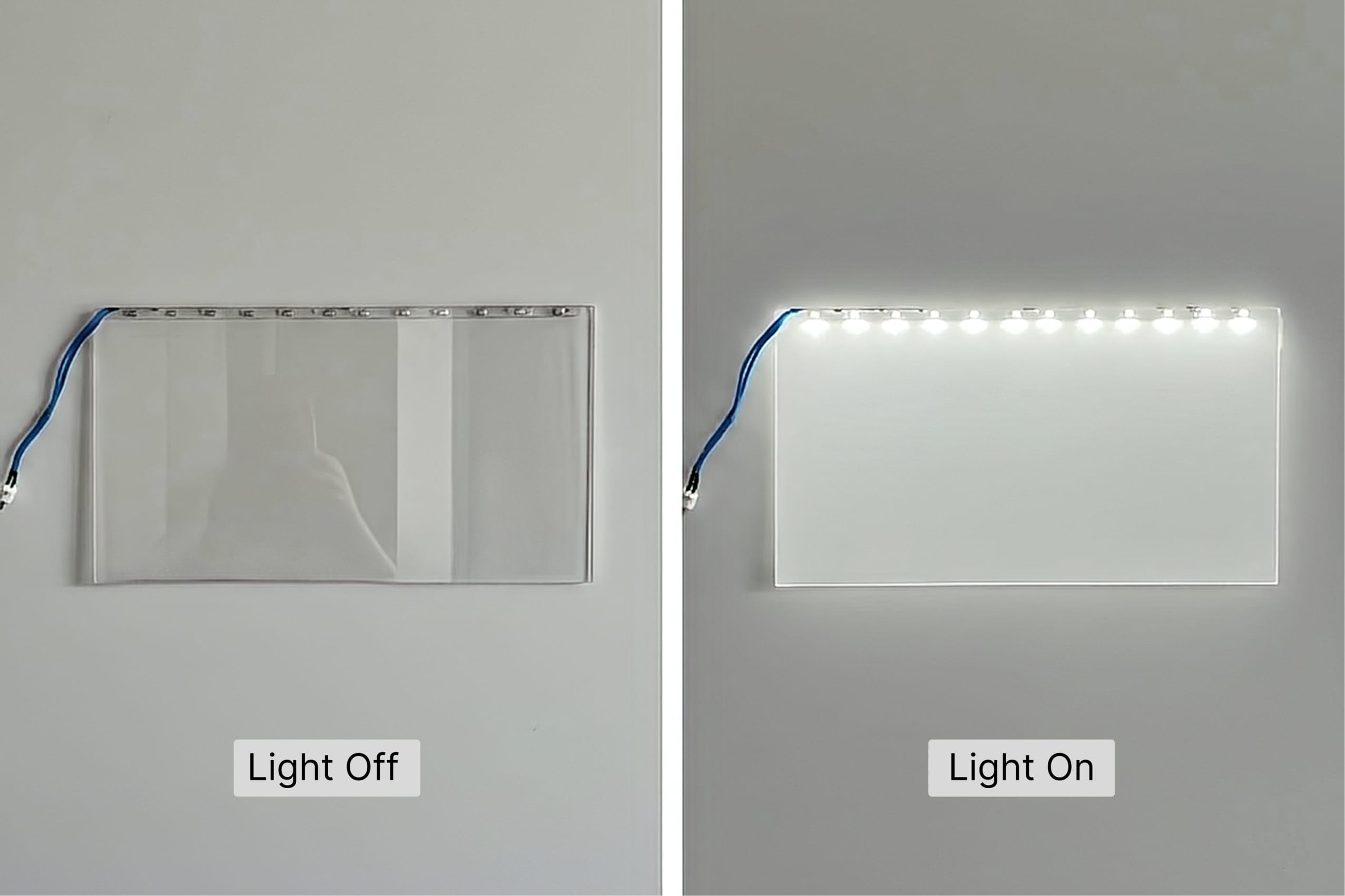

Diffusive LGP

The Diffusive Light Guide Plate (Diffusive LGP) is an advanced optical solution designed to deliver smooth, uniform illumination through bulk light diffusion rather than surface laser engraving. By embedding precisely controlled diffusive particles within the PMMA substrate, the light is scattered evenly throughout the panel, producing consistent brightness with minimal visual artifacts.

This technology eliminates the need for laser dot patterns or silk-screen printing, making Diffusive LGPs especially suitable for compact, medium-sized panels and applications where simplicity, reliability, and visual comfort are critical.

Certifications

Technical Specifications

| Attribute | Value / Range | |

|---|---|---|

| Material | Diffusive optical-grade PMMA | |

| Thickness | Typically 2 mm – 15 mm (custom options available) | |

| Maximum Recommended Width | ≤ 600 mm | |

| Surface Treatment | None (bulk diffusion) | |

| Light Input | Single-sided or double-sided edge lighting | |

| Processing | Cutting, machining, thermoforming | |

| UV Resistance | Suitable for indoor & outdoor use | |

| Service Life | Approx. 8–10 years |

Seamless Illumination Transition

Uniform Illumination: Smooth, visually comfortable light without dot patterns.

Simplified Optical Stack: Can be used without additional diffuser sheets in certain designs.

Cost-Effective Solution: Eliminates laser engraving and printing processes.

Design Flexibility: Easily adaptable to different shapes and layouts.

Dual Light Input: Supports single-sided or double-sided edge lighting.

Design & Integration Guidelines

Recommended Panel Size

Diffusive LGPs perform best in small to medium formats, particularly for panels with a width not exceeding 600 mm, where uniformity can be maintained without surface extraction patterns.

LED Configuration

- Optimized for edge-lit LED arrangements.

- Works well with both single-edge and dual-edge input designs.

- Simpler LED layout compared to laser-etched LGPs.

Diffuser Usage

Optional diffusers can be used to further soften luminance or meet glare requirements.

In many applications, no additional front diffuser is required.

More Information

Custom Cutting, Machining & Fabrication

Every Light Guide Plate (LGP) is fully customizable to meet your specific design and assembly requirements.

Advanced fabrication technology ensures precision cutting, optical clarity, and consistent quality for all applications.

Capabilities include:

- CNC cutting, milling, and drilling

- Laser engraving for light extraction patterns

- Edge finishing and polishing for high transparency

- Tight-tolerance machining for perfect alignment

Supports both prototype development and mass production with stable, repeatable optical performance.

Typical Tolerances Properties for Optical Grade PMMA

| Property | Typical Value / Tolerance |

| Thickness | ± 0.1 mm (3 to 15mm) |

| Dimensional (length × width) | ± 0.3 mm |

| Material clarity / defects | No inclusions, bubbles, scratches visible; optical grade |

| Uniformity | ≥ 85% uniformity depending on size; for small size often higher |

| Thermal expansion | ~ 7 × 10⁻⁵ / °C |