Light Guide Plate (LGP)

Product Details:

- Material: PMMA.

- Thickness Range: Standard 1–10 mm; custom options available for 12 mm and 15 mm.

- Sheet Sizes: Custom, with a maximum size of up to 1250 × 3050 mm.

- Light Uniformity: >85%.

- Dot & Pattern Options: Various microdots, microlinear, and hot-pressed patterns.

- Fire Safety: Certified to UL 94 (HB)

- Edge & Cut Options: Laser cutting, edge polishing, and custom notching.

Description

The Light Guide Plate (LGP) is a critical optical component designed to transform point or line light sources, such as LEDs, into a uniform, high-efficiency surface light. At Hexatron Technologies, our LGPs are manufactured using premium Mitsubishi optical-grade clear PMMA, ensuring maximum light transmission and long-term clarity without yellowing.

By utilizing state-of-the-art laser engraving technology, we produce light guides with exceptional uniformity (exceeding 85%) and the capability to cover large illuminated surfaces up to 2×4 meters. This precision allows for the creation of ultra-slim, edge-lit luminaires that maintain consistent brightness across the entire panel. Our commitment to flexibility means we offer custom cutting, machining, and fabrication with no Minimum Order Quantity (MOQ), supporting both prototyping and large-scale production.

We offer the following types of LGP:

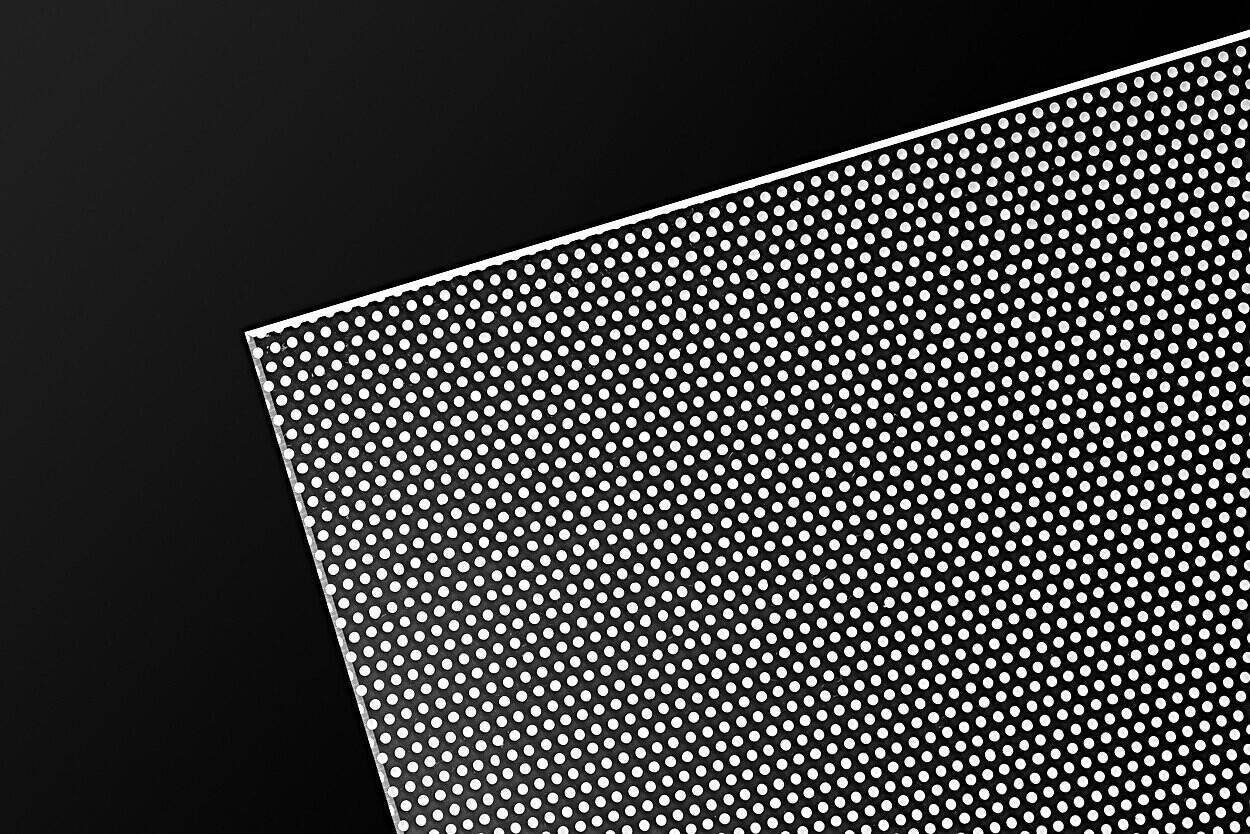

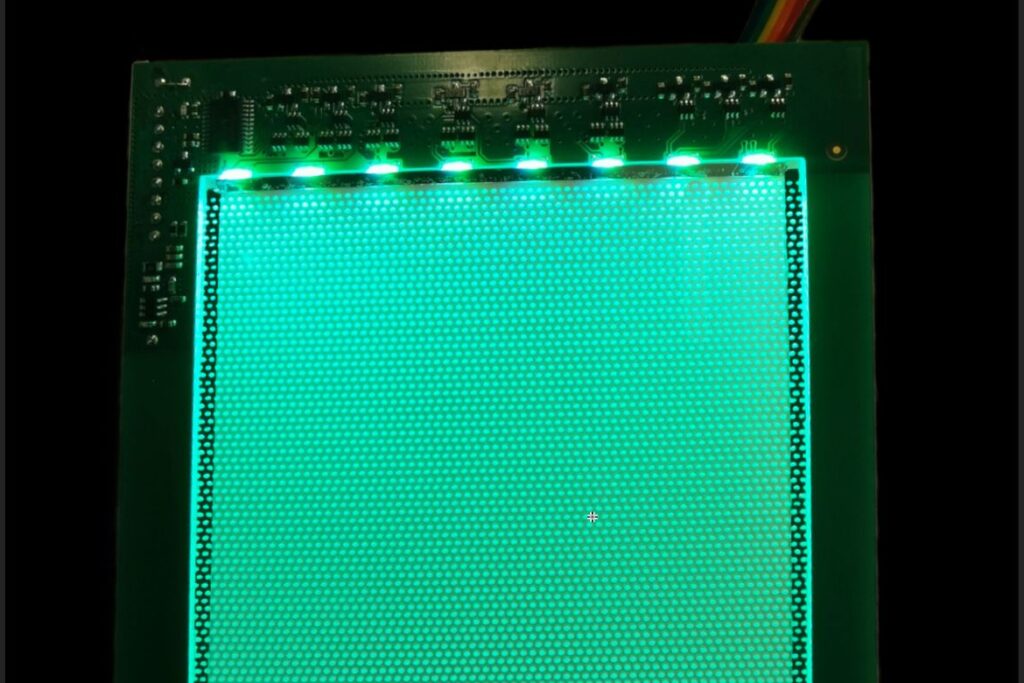

Laser LGP

One of the most used ones. The Laser LGP represents the pinnacle of backlighting technology. Unlike traditional silkscreen methods, our laser-engraved dot patterns are digitally optimized for each specific panel size.

Laser etching ensures perfect light distribution even in large-format signage and architectural panels. The laser process creates permanent, high-precision micro-structures that offer superior brightness and a longer lifespan compared to printed alternatives.

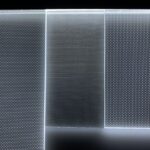

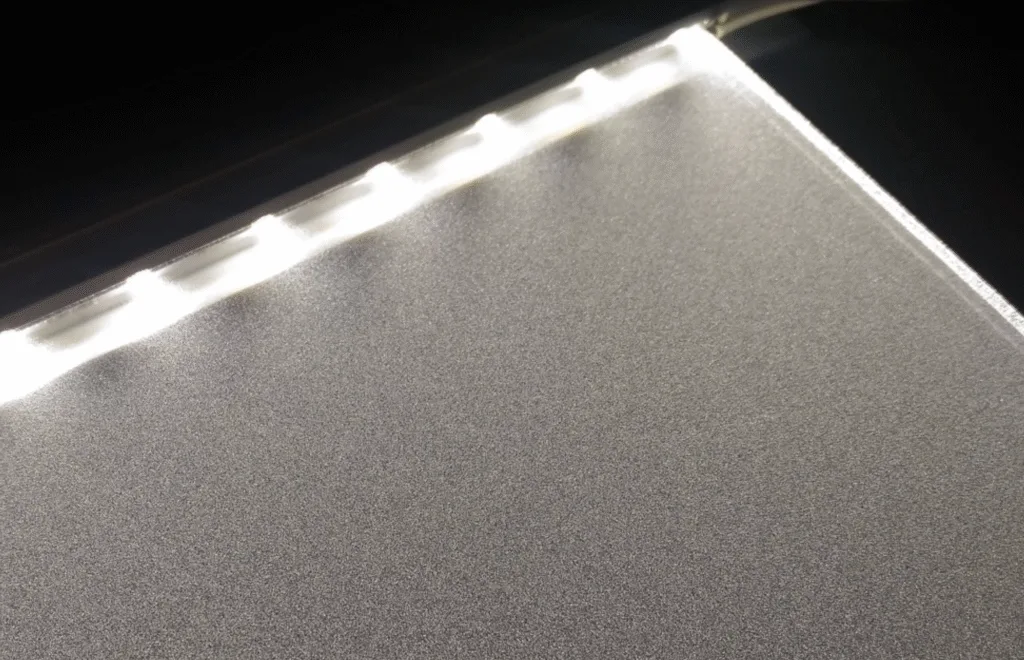

Diffusive LGP

The Diffusive LGP is designed for applications requiring soft, visually comfortable light without visible hotspots.

/By integrating advanced diffusion properties directly into the light guide, this product works without white reflector external diffuser.

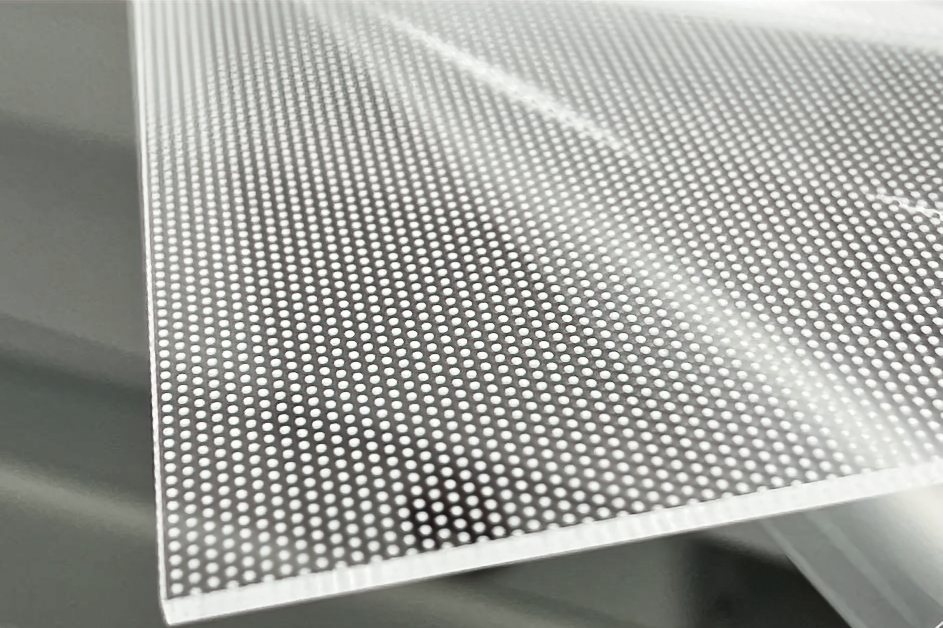

Thin LGP

Specifically engineered for ultra-slim luminaires and space-constrained applications, these plates maintain high structural integrity and optical performance at reduced thicknesses.

Our ultra-thin Light Guide Plate enables exceptionally slim backlighting solutions. When integrated with custom electronic controls, it delivers dynamic lighting effects that enhance product aesthetics and maximize visual impact.