Custom Projects

We turn your ideas into reality. Whether it’s a small custom order or a large-scale production. Our team works closely with you to manufacture products exactly to your specifications, ensuring top-quality results every time.

Unique challenges are welcomed and we will provide flexible manufacturing options tailored to your needs. In most cases, no minimum order quantity (MOQ) applies, making it easy for designers, engineers, and OEMs to develop new products, or innovative lighting solutions.

Description

The process begins with a detailed review of your design requirements, drawings, or performance goals. Our engineering team then recommends the most suitable materials, optical structures, and fabrication methods. Once specifications are finalized, samples or prototypes are produced for validation. After approval, production scales up to full manufacturing, maintaining consistent quality through precision cutting, machining, and optical testing. Throughout every stage, you receive dedicated technical support and clear communication to ensure your project achieves the desired light diffusion, reflection, or transmission performance.

Bellow are some examples of recent projects:

Optical Components & Prismatic Solutions

- Low-UGR (<19) Prismatic Sheet: Developed according to the optical and safety requirements, featuring TP(a) fire rating and anti-UV coating for long-term performance.

- Opal Prismatic Sheet: Produced with custom light transmittance and thickness options to achieve the desired balance of diffusion and brightness.

- Custom Prism Tooling: Affordable extrusion rollers engineered to create unique prism geometries matching the requested design and optical simulation data.

- Flexible Opal Diffuser Lens: Designed with TPE hooks for continuous linear fixtures up to 30 m, for architectural or large-area lighting.

- Thermoformed Diffuser Sheet: Manufactured to fit curved or complex shapes, maintaining uniform luminance and smooth diffusion across all surfaces.

Light Guide Projects

- Laser-Engraved Light Guide Plates (LGP) – precision laser engraving for extra-long formats up to 19 ft (≈ 5.8 m) with narrow widths; engineered for seamless light extraction and high optical efficiency.

- Large-Area Light Guide Assembly: 6 × 2 m optical panel integrating back reflector and front diffuser, bonded to aluminum for excellent heat dissipation and easy installation.

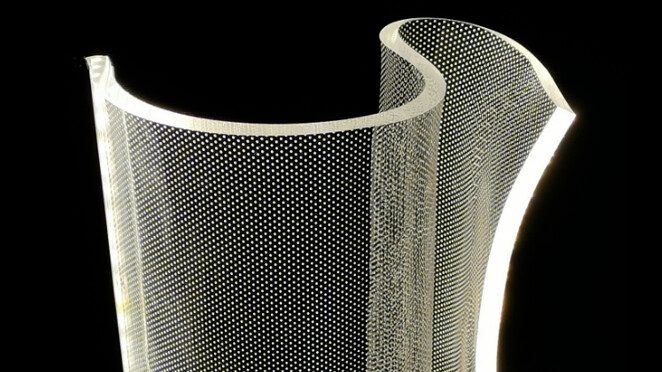

- Custom Light Guide Shapes & Edge-Lit Designs: Laser and CNC-cut or molded to any geometry, supporting both flat and curved configurations for signage, luminaires, or decorative panels.

- Micro-Patterned LGPs: Surface-engraved or printed dot patterns designed according to optical simulation data.

- Thin Light Guide Films (LGF): Ultra-thin and flexible light guides for portable devices.

- Integrated Light Modules: Complete assemblies combining LEDs, light guides, diffusers, and reflectors for plug-and-play illumination systems tailored to OEM specifications.

Special Lenses

- Fire-Rated Polycarbonate Lens: Made from UL94 V-0 polycarbonate for enhanced flame resistance, available in tinted colors with anti-scratch coating for use in medical devices, instruments, or safety enclosures.

- Linear Batwing and Asymmetric Lenses: Designed as continuous lens for linear luminaires requiring beam control.

- Black-to-Opal Diffuser Lens: Innovative optical sheet that appears black when off and transforms to opal white when illuminated, providing elegant light diffusion and glare control for architectural and decorative lighting.

- Lenses for Appliances and Medical Devices: Optical solutions that deliver uniform illumination, and elevate both functionality and design.