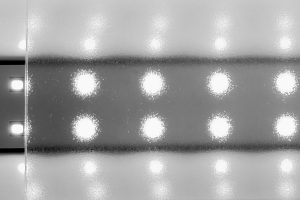

LED Diffuser Sheets

Product Details:

- Material Options: PMMA, PS and PC.

- Light Transmittance Range: 55% to clear sheets.

- Thickness Range: Standard 1.2–3 mm; custom options for the prismatic ones: 4 mm and 5 mm.

- Sheet Sizes: Standard 1220 × 2440 mm, with maximum size up to 1250 × 3050 mm.

- Fire Safety: Certified to UL 94 (HB, V2, V0) and TP(a) rating for selected models.

- Surface: Silk and Frost Matte.

Description

At Hexatron Technologies, we extrude high-performance diffuser sheets using three premium optical-grade materials: Polymethyl Methacrylate (PMMA), Polycarbonate (PC), and Polystyrene (PS). Each material is engineered to meet the unique needs of LED lighting, architectural design, displays, and industrial applications.

Our diffuser sheets are available in standard thicknesses as well as custom thickness options. With a wide range of light transmittance levels, from opal sheets (~55% transmittance) for maximum diffusion of high-power LEDs to translucent and clear sheets (up to 94% transmittance) for maximum brightness, you can select the perfect solution for your project.

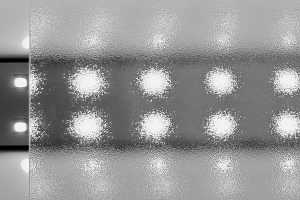

Strong Diffusion

Designed for maximum glare reduction and light uniformity, strong diffusion sheets are ideal for high-power LED sources and applications requiring excellent visual comfort.

- Typical transmittance: ~50–70%

- Strong masking of LED hot spots

- Recommended for office, education, healthcare, and public spaces

| Product Code | Surface Finishes | Thickness mmin | Transmittance (%) | Matte Surface | Light Diffusion | Thickness in mmin |

|---|---|---|---|---|---|---|

| S55 | Frost/Glossy | 1.5 | 55 |  |  | 0.059 |

| Plexi58 Silk | Silk/Glossy | 1.5, 2.0 & 3.0 | 58 |  |  | 0.059, 0.078, 0.118 |

| Plexi58 Frost | Frost/Glossy | 1.5, 2.0 & 3.0 | 58 | 0.059, 0.078, 0.118 | ||

| Poly60 | Frost/Glossy | 1.0 1.2 1.5 2.0 | 60 |  |  | 0.003, 0.047, 0.059, 0.078 |

| Plexi70 Silk/Textured* | Silk/Textured | 1.5, 2.0 & 3.0 | 70 |  |  | 0.059, 0.078, 0.118 |

| Poly70* | Frost/Glossy | 0.8, 1.0, 1.2, 1.5, 2.0, 3.0 | 70 |  |  | 0.002, 0.003, 0.047, 0.059, 0.078, 0.118 |

| S70* | Frost/Glossy | 1.0, 1.2 & 1.5 | 70 |  |  | 0.003, 0.047 & 0.059 |

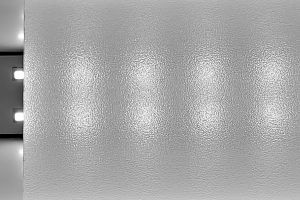

Medium Diffusion

A balanced solution offering uniform light distribution while maintaining higher brightness compared to strong diffusion options.

- Typical transmittance: ~75–86%

- Reduced LED visibility with improved efficiency

- Suitable for general lighting and architectural applications

- Ideal compromise between comfort and output

| Product Code | Surface Finishes | Thickness mmin | Transmittance (%) | Matte Surface | Light Diffusion | Thickness in mmin |

|---|---|---|---|---|---|---|

| S75* | Frost/Glossy | 1.2 & 1.5 | 75 |  |  | 0.047 & 0.059 |

| Plexi75 Silk | Silk/Glossy | 1.2 & 1.5 2.0 | 75 |  |  | 0.047, 0.059 & 0.078 |

| Plexi75 Frost* | Frost/Glossy | 1.2 & 1.5 2.0 | 75 | 0.047, 0.059 & 0.078 | ||

| S80* | Frost/Glossy | 1.2 & 1.5 | 80 |  |  | 0.047 & 0.059 |

| Poly80* | Frost/Glossy | 0.8 1.0 1.2 1.5 2.0 | 80 |  |  | 0.002 0.003 0.047 0.059 0.078 |

| Plexi85 Silk | Silk/Glossy | 1.5, 2.0 & 3.0 | 85 |  |  | 0.047, 0.059 & 0.118 |

| S86* | Frost/Glossy | 1.2 & 1.5 | 86 |  |  | 0.047 & 0.059 |

High Transmission

Engineered for maximum light output, these sheets provide minimal diffusion while maintaining optical clarity.

- Typical transmittance: up to 94%

- High brightness with subtle diffusion

- Ideal for signage, displays, light boxes, and decorative lighting

| Product Code | Surface Finishes | Thickness mmin | Transmittance (%) | Surface Image | Light Refraction | Thickness in mmin |

|---|---|---|---|---|---|---|

| Poly90 Gloss | Frost/Glossy | 1.0, 1.2, 1.5 & 2.0 | 90 |  |  | 0.003 0.047 0.059 0.078 |

| Plexi90 Silk | Silk/Glossy | 1.5, 2.0 & 3.0 | 90 |  |  | 0.047 0.059 |

| Plexi90 Frost* | Frost/Glossy | 1.5, 2.0 & 3.0 | 90 | 0.047 0.059 | ||

| S92 | Frost/Glossy | 1.5 | 92 |  |  | 0.059 |

| S94 | Frost/Glossy | 1.5 | 94 |  |  | 0.059 |

| Plexi94 Silk | Silk/Glossy | 1.2, 1.5 & 2.0 | 94 |  |  | 0.047 0.059 0.078 |

Deep dive into the different diffusion grades on their respective product pages.