Light Guide Plates (LGP): The Hidden Technology Powering Illumination

A Light Guide Plate (LGP) is a thin, transparent optical sheet typically made from optical-grade acrylic (PMMA) or polycarbonate (PC). It is designed to distribute light evenly across its surface by guiding light from edge-mounted LEDs and emitting it uniformly through the front face.

Originally developed for LCD backlight modules (BLUs), the LGP has evolved into a core optical component in LED panel lighting, architectural illumination, and decorative display systems.

The unique value of an LGP lies in its ability to transform directional LED light into a wide, uniform, and soft light source without glare, even in ultra-thin luminaires.

How Does LGP Work?

- Edge-Lit Illumination: LEDs are placed along one or more edges of the LGP. These edge-lit LEDs inject light into the plate.

- Internal Reflection: The light travels through the plate via total internal reflection (TIR), maintaining brightness and directionality within the optical guide.

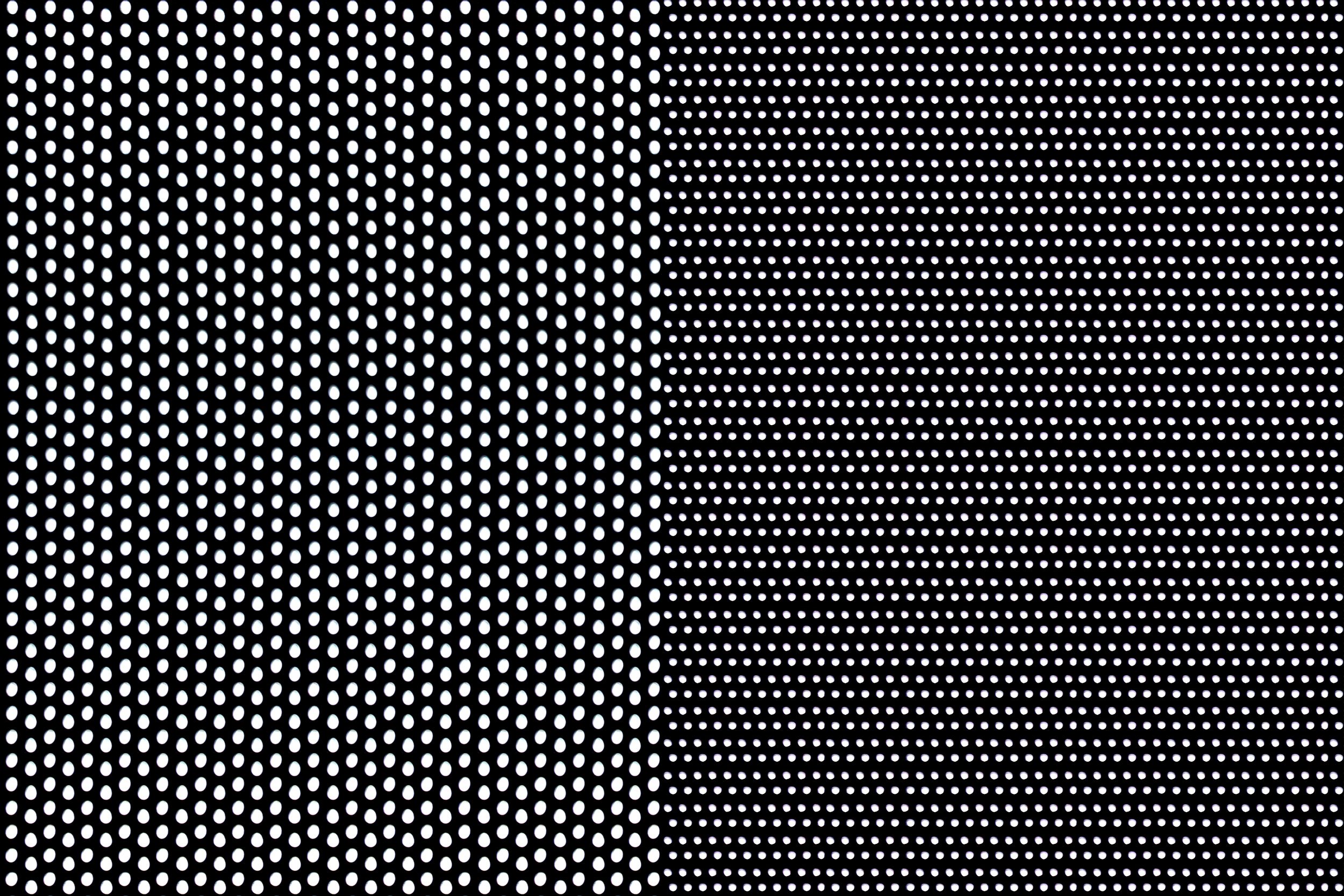

- Patterned Extraction: Micro-patterns or laser-engraved dots on the surface of the plate scatter the light outward in a controlled way.

- Uniform Output: The dot density and size gradually change from the LED edge to the center of the plate to compensate for light attenuation, resulting in consistent brightness and uniform illumination.

This mechanism allows for extremely slim lighting solutions, minimizing the need for bulky housings.

Precision Engineering of Dot Patterns

Achieving high optical performance in an LGP light guide panel depends on accurate dot pattern design. Optical engineers use advanced simulation software to model how light travels inside the PMMA LGP and to optimize dot density, spacing, and distribution.

- Dot Size & Density: Adjusted to control light extraction and balance brightness.

- Gradient Design: Patterns are denser farther from the LED source to offset light loss.

- Algorithmic Optimization: Proprietary optical algorithms simulate multiple scenarios to find the most efficient configuration.

Laser Light Guide Plate Manufacturing

Once the ideal pattern is finalized, it is transferred to production using laser engraving technology:

- A high-precision laser plotter engraves microscopic dots directly onto the surface of the acrylic LGP sheet.

- Laser intensity and pulse frequency are finely tuned to ensure uniform pattern depth and spacing.

- Laser-engraved LGPs provide excellent durability, optical consistency, and long product life, outperforming printed patterns in demanding environments.

This laser light guide plate manufacturing method ensures stable brightness, high efficiency, and premium optical clarity, making it suitable for advanced LED lighting systems and display applications.

Laser-engraved patterns offer superior durability and consistency over printed patterns, especially in environments requiring longer product life and stable optical properties.

The Light Guide Plate (LGP) is a cornerstone of modern optical lighting design. Its precision-engineered dot patterns, PMMA-based clarity, and laser-engraved uniformity enable ultra-slim, efficient, and visually appealing lighting solutions.

For more insights into LED light guide plate design, optical uniformity, or to request samples and technical collaboration, please contact us or explore resources like LEDs Magazine for deeper technical reading.