Opto Films

Product Details:

- Material Options: PET and Polycarbonate.

- Thickness Range: 100- 500 μm.

- Light Transmittance Range: From 50% to 90%

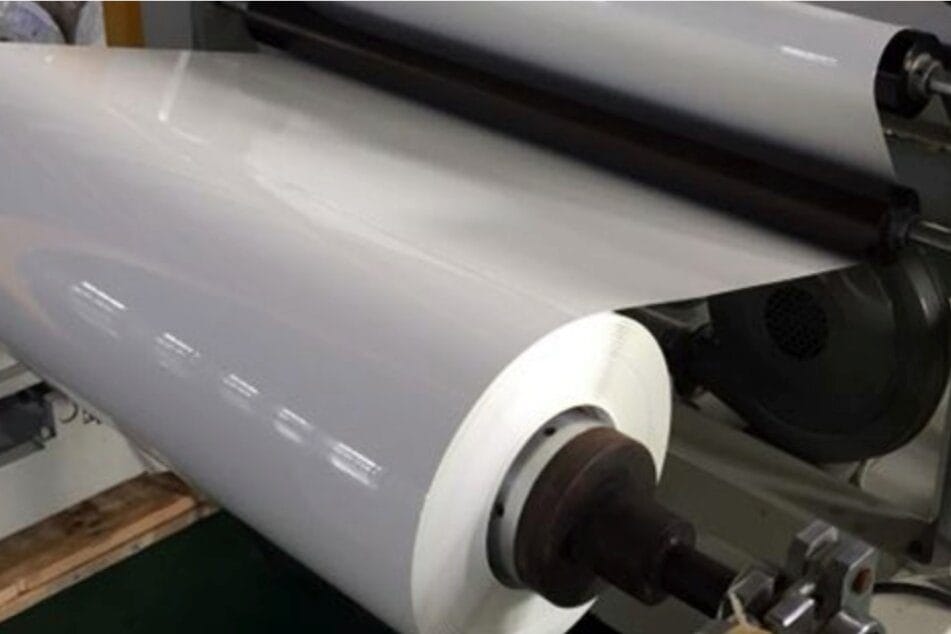

- Roll Sizes: Standard width: 1220 mm. Length range from 100 to 1000 meters.

- Surface: Finishes available in different frost and matte levels.

Description

Opto Films are precision-engineered optical polymer films designed to control, enhance, and manage light within advanced LED lighting, display, and backlighting systems. By selectively diffusing, reflecting, or blocking light, these films enable manufacturers and lighting designers to achieve uniform illumination, high system efficiency, and controlled visual output in compact and ultra-thin designs.

At Hexatron Technologies, our Opto Films are developed to integrate seamlessly with Light Guide Plates (LGPs), diffuser sheets, and LED modules. They form a critical layer in the “optical stack”, ensuring that every lumen is directed precisely where it is needed. Available in both PET and Polycarbonate (PC) materials, our films offer a versatile range of thicknesses (100–500 μm) and surface finishes to meet the most demanding optical specifications.

Diffuser Films: Smoothing and Uniformity

Diffuser Films are engineered to eliminate “hot spots” and smooth out luminance variations across a surface. By scattering light at the microscopic level, these films improve visual comfort and ensure a perfectly uniform glow, even in ultra-thin LED panels where the light source is close to the viewing surface.

Reflector Films: Maximizing System Efficiency

Reflector Films are high-reflectivity layers placed at the back of the optical stack. Their primary function is to redirect backward-emitted light toward the intended illumination surface. By minimizing light loss within the fixture, our reflector films significantly increase the overall Luminous Efficacy of the system. We offer both PET and PC-based white reflector films, allowing designers to choose the best balance of thermal stability and reflectivity for their specific application.

Light-Blocking Films: Precision and Contrast

Light-Blocking Films (also known as masking films) are opaque or low-transmission films used to define illumination zones and prevent unwanted light leakage. These films are critical for improving contrast in displays and ensuring “clean” edges in architectural linear lighting. By effectively containing light within designated paths, they allow for high-precision optical designs and prevent “ghosting” or light bleed in multi-zone lighting systems.

The Optical Stack: A Complete Solution

Opto Films are most effective when used as part of a coordinated optical system. Hexatron specializes in providing the entire “bundle” of components required for professional LED backlighting:

LED Source → Light Guide Plate (LGP) → Opto Films → Final Light Output

By combining our Laser LGP technology with the appropriate Opto Films, manufacturers can achieve industry-leading uniformity and efficiency. Our technical team can assist in selecting the ideal combination of diffuser, reflector, and light-blocking layers to optimize your specific luminaire design.