Laser LGP

Product Details:

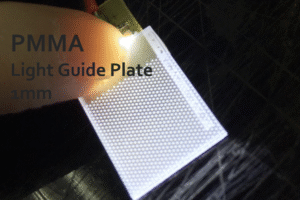

- Material: PMMA.

- Thickness Range: Standard 1–10 mm; custom options available for 12 mm and 15 mm.

- Sheet Sizes: Custom, with a maximum size of up to 1250 × 3050 mm.

- Light Uniformity: >85%.

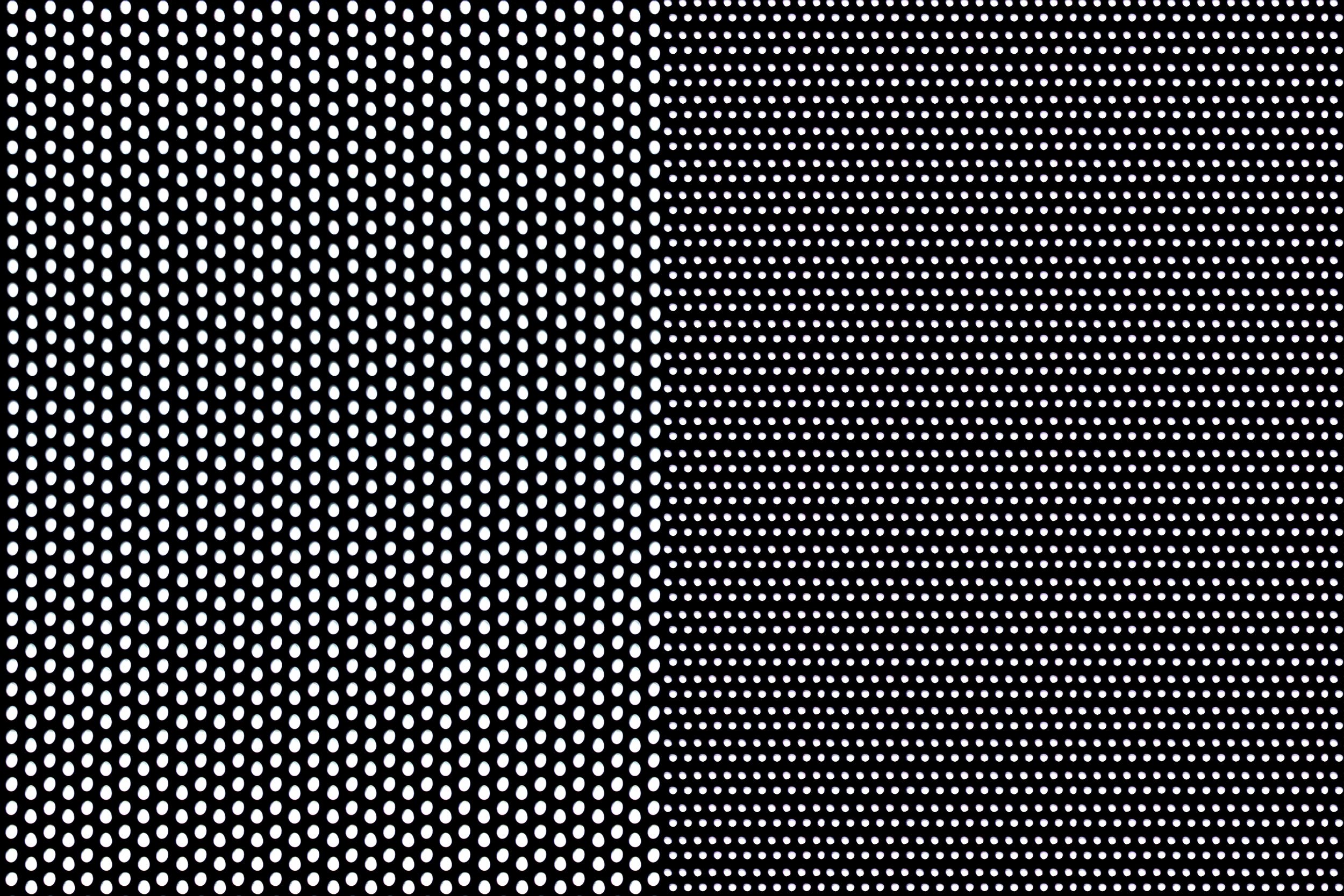

- Dot & Pattern Options: Various microdots, microlinear, and hot-pressed patterns.

- Fire Safety: Certified to UL 94 (HB)

- Edge & Cut Options: Laser cutting, edge polishing, and custom notching.

Description

Our Light Guide Plate (LGP) is made from Mitsubishi optical-grade clear PMMA, the best material to reach the highest uniformity and luminaire efficiency. The state-of-the-art laser engraving machines allow us to make light guides with the largest illuminated surface, up to 2×4 meters. That’s a unique competitive advantage. The LGP thickness could be any from 2mm up to 15mm. Our inventory of clear sheets allows us the flexibility to serve customers with any special request without MOQ.

We can supply the complete optical plastic parts for manufacturers:

- The back reflective sheet.

- The LGP itself, and

- The front diffuser sheet is in matte opal or clear prismatic surface for UGR<19 luminaires.

Homogeneous light distributions across the panel.

- Design of the laser dotting density according to each panel size.

- UV stability.

- No MOO and samples without a development fee.

- Any shape.

Most common applications:

- Slim LED panel lights and architectural linear fixtures.

- Signage and light boxes.

- Displays.

- Emergency lighting.

- Automotive lighting.

- Point of purchase display.

Complement Products

Lighting manufacturers often purchase Light Guide Plates (LGPs) as part of a complete lighting bundle, including:

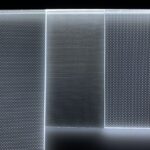

Diffuser sheet options:

- Polystyrene (PS) or PMMA opal sheets of 1.5–2 mm thickness, or

- Fire-rated Polycarbonate (PC) sheets of 1–1.5 mm, or

- PC diffuser films for ultra-slim designs, or anti-glare UGR<19 prism optics in 0.5 mm thickness.

Light Guide Plates: Most commonly used thicknesses are 3 mm and 4 mm, delivering uniform light distribution.

Reflective Films: Available in various thicknesses, with 225 µm being the most popular. As an optional service, we can bond the reflective film to the LGP at no additional cost, simplifying assembly.

Diffusive LGP

Description

Our diffusive Light Guide Plates (LGPs) feature embedded optical materials that scatter light evenly across the panel, ensuring uniform illumination. By incorporating diffusive particles within the PMMA substrate, these LGPs deliver smooth, consistent brightness without relying solely on laser surface patterns.

Ideal for backlit displays, signage, and LED panels without a diffuser cover. Our scattering LGPs combine high optical performance with easy integration, offering a reliable solution for modern lighting applications.

- Can be cut arbitrarily into the required size, no laser etching or silk printing required.

- Can be processed into any shape. It can be thermoformed.

- High light conversion rate, light effect is uniform.

- Can be used indoor and outdoor. The service life is up to 8-10 years.

- Can be used both, as single-sided and double-sided light input.

Suitable for specific applications that are not longer than 600mm in width

- Decoration: background light, exhibition shelves.

- Lighting: Flat panel lights.

- Advertising: Thin light boxes, logo signs, etc.

Thin LGP

Description

Our 1 mm thin Light Guide Plate delivers uniform and efficient illumination in ultra-slim designs, making it ideal for backlit displays, signage, and compact LED panels. It ensures even light distribution across the entire surface. Available in custom sizes and shapes.

We offer comprehensive added-value services to simplify your LED lighting projects. Our solutions include integration of LED modules, connectors and wiring, and thermal management components. Additionally, we provide support for complementary components like bonded diffuser films, reflective films, and control modules.

More Information